In the fast-paced world of packaging, efficiency and precision are paramount. Enter form-fill-seal (FFS) machines, versatile equipment that revolutionize the packaging process by forming the package, filling it with the product, and sealing it, all in one seamless operation. These machines are crucial for various industries, from food and beverages to pharmaceuticals and cosmetics. However, to harness the full potential of FFS machines, it’s essential to choose the right films and rollers for their operation.

Understanding the Role of Films and Film Rollers

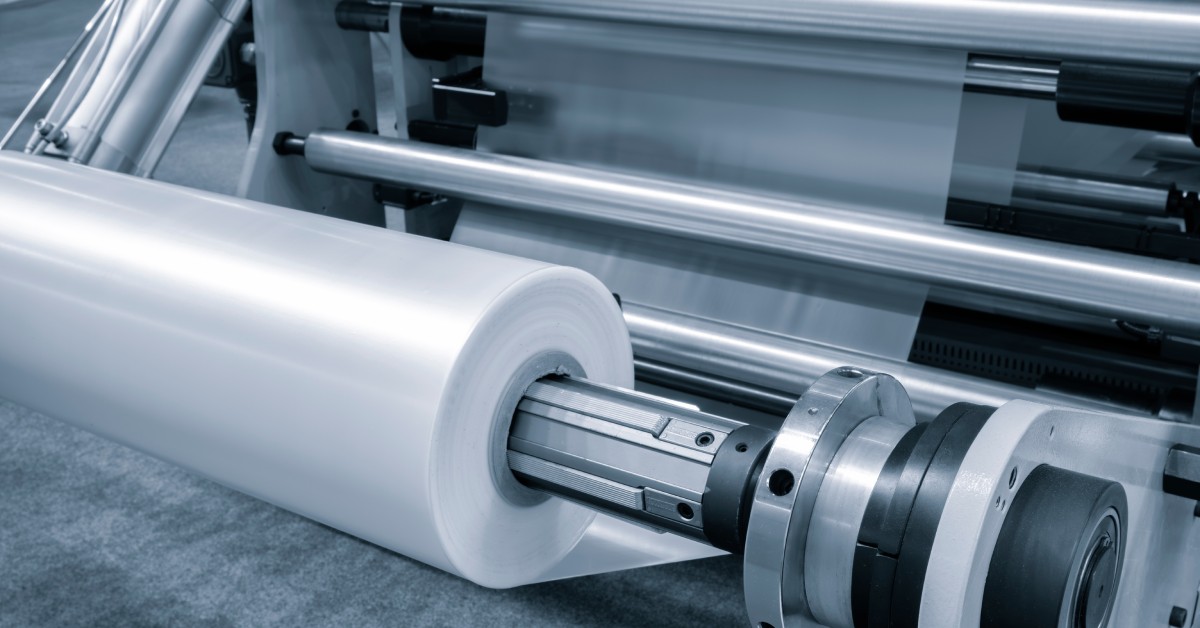

Films and film rollers are the backbone of FFS machines. They not only create the physical package but also ensure its integrity and appearance. Choosing the right films and rollers is vital for achieving optimal performance and quality in the packaging process.

Films vs. Rollers

Films serve as the fundamental packaging material and come in various types to suit different product requirements, including polyethylene, polypropylene, and multilayer films. Their properties, such as tensile strength, thickness, and barrier capabilities, directly affect the durability and protection of the packaged product.

On the other hand, rollers play a critical support role by ensuring the smooth and precise movement of the film through the FFS machine. The rollers help maintain consistent tension and alignment, which is essential for producing uniform and accurate seals. While films determine the final package’s look and feel, rollers facilitate the seamless operation of the packaging process.

Key Factors To Consider When Choosing Films and Film Rollers

Selecting the right films and rollers requires a careful assessment of several critical factors. Here’s what you need to keep in mind:

Film Type and Properties

Films come in various materials, such as polyethylene, polypropylene, and laminate. Each type has unique properties, including strength, flexibility, and barrier capabilities. Assess the specific needs of your product to choose a film type that ensures protection and durability. For example, food products may require high-barrier films to prevent spoilage, while pharmaceuticals may need puncture-resistant films for safety.

Compatibility With FFS Machines

Not all films and rollers are compatible with every FFS machine. Ensure that the materials you select are suitable for your specific equipment. This compatibility affects the efficiency of the packaging process and the quality of the final product. Consult with your machine manufacturer or supplier for recommendations.

Environmental Considerations

Sustainability is a growing concern in the packaging industry. Opt for films that are recyclable or biodegradable to minimize environmental impact. Consider the sourcing of materials and their lifecycle when making your selection. Additionally, choose film rollers that are energy-efficient and durable to reduce waste and maintenance costs.

Benefits of Using High-Quality Films and Rollers

Investing in top-notch films and rollers offers several significant advantages:

Improved Efficiency

High-quality materials enhance the operational efficiency of FFS machines. They reduce downtime caused by film breakage or roller malfunction, leading to smoother and faster production runs. Additionally, they require less frequent replacements, saving time and resources.

Enhanced Product Quality

Superior films provide better protection against external factors like moisture, light, and oxygen, ensuring that your products remain fresh and safe. High-quality rollers ensure precise film handling, resulting in consistent and attractive packaging. This improves the overall appearance and appeal of your products.

Operational Safety

Using reliable films and rollers minimizes the risk of machine malfunctions and accidents. This not only protects your workforce but also reduces maintenance costs and extends the lifespan of your equipment. It also leads to more consistent and reliable packaging results.

Best Practices for Selecting Films and Rollers

To make informed decisions and optimize your packaging process, follow these best practices:

Conduct Thorough Testing

Before fully integrating a new film or roller into your production line, conduct extensive testing. Evaluate how the material performs under various conditions and address any issues that arise during the trial phase. This ensures that the materials meet your specific requirements and are compatible with your equipment.

Consult With Experts

Leverage the knowledge and experience of industry experts. Consult with suppliers and technical advisors who can provide insights and recommendations based on your specific needs and challenges. This can save you time and resources in the long run.

Stay Updated on Industry Trends

The packaging industry is continually evolving, with new materials and technologies emerging regularly. Stay informed about the latest trends and innovations to ensure your packaging solutions remain cutting-edge. Attend trade shows, conferences, and workshops to network with professionals and gain valuable insights.

Maintaining Films and Rollers

Proper maintenance and alignment of rollers are as important as selecting the appropriate film type, as both components work together to achieve the desired packaging results.

Maintenance Checklist for Films and Rollers

Films Maintenance

- Inspect for damage: Regularly check the film for any signs of tears, punctures, or other damages that may compromise its integrity.

- Cleanliness: Ensure films are kept clean to prevent contamination. Use appropriate cleaning materials that do not degrade the film’s properties.

- Storage conditions: Store films in a controlled environment, away from direct sunlight, excessive heat, or moisture, to maintain their quality.

- First-in-first-out (FIFO): Implement FIFO in film storage to ensure older films are used first, avoiding the degradation of materials over time.

- Monitor usage: Track film usage and performance to identify any recurring issues or trends that may need addressing, such as frequent breakages.

Rollers Maintenance

- Regular lubrication: Apply suitable lubricants to rollers to ensure smooth movement and reduce friction, preventing wear and tear.

- Alignment checks: Periodically check and adjust roller alignment to ensure consistent and precise film handling.

- Surface inspection: Inspect roller surfaces for wear, scratches, or build-up of debris. Clean or replace rollers as necessary.

- Tension adjustments: Monitor and adjust film tension settings to prevent excessive strain on rollers, which could lead to premature failure.

- Replace worn components: Keep an inventory of spare rollers and components to facilitate quick replacements and minimize downtime during production runs.

The Future of Films and Rollers

The future of films and rollers in FFS machines looks promising, with several exciting developments on the horizon:

Sustainable Materials

Advancements in sustainable materials will continue to drive innovation. Expect to see more eco-friendly options that offer high performance with minimal environmental impact. This includes films made from renewable resources and rollers with improved energy efficiency.

Smart Technologies

Integration of smart technologies, such as IoT-enabled rollers, will enhance monitoring and maintenance. These technologies can provide real-time data on the condition of your films and rollers, allowing for proactive maintenance and optimization.

Customization and Flexibility

Future films and rollers will offer greater customization and flexibility, enabling FFS machine manufacturers to tailor their packaging solutions to specific product requirements and market demands. This will lead to more efficient and cost-effective production runs.

Start Making the Right Packaging Choices Today

In the packaging industry, choosing the right films and film rollers for FFS machines can make or break your operation. By selecting high-quality materials and following best practices, you can achieve improved efficiency, enhanced product quality, and operational safety. Stay ahead of industry trends and innovations to ensure your packaging solutions remain competitive.

Your perfect packaging starts with the right choices. Start making them today.